My off-grid systems have been online for the last 5 years, installed in 2006 and basically consists of a primary 24v setup and a secondary 12v setup. My scope for this setup is twofold,

- Have a backup system in case of a system outage. Although it will not power and provide all my electricity needs, at least it will handle the basic.

- Reduce my electricity consumption.

System DC voltage: 24v

Solar Panels: 4 x 80W Sharp panels, totalling 320W.

Wind turbine: Modified 400W Air-X Marine wind turbine. Details of the modifications can be found in this post.

Batteries: 2 set of 24v fork-lift batteries. Total of 12 batteries per set @ 2v per cell. (about 8 years old when I took them and unfortunately had been heavily abused - sat discharged and lacking electrolyte for a long time and therefore the plates have been exposed to the air and most probably are heavily sulphated). No idea about their current capacity; although I'll measure it and post my findings in a separate post, however they are very, very heavy and each cell physical size is:

Set 1: 20cm width x 15.5cm depth x 40cm tall

Set 2: 20cm width x 12cm depth x 46cm tall

Note: These batteries have been changed to a new set. Details can be found here.

Inverter: Modified BEST FORTRESS UPS 600VA. This is basically a computer UPS, with these modifications;

- Removed the two internal 7AHr batteries and instead redirected the UPS to get it's power from an external source, i.e. the fork-lift batteries.

- Removed the internal beeper which acted as an alarm when the UPS was operating on batteries. Obviously in this case I didn't want the beeper to sound for 24 Hrs a day!

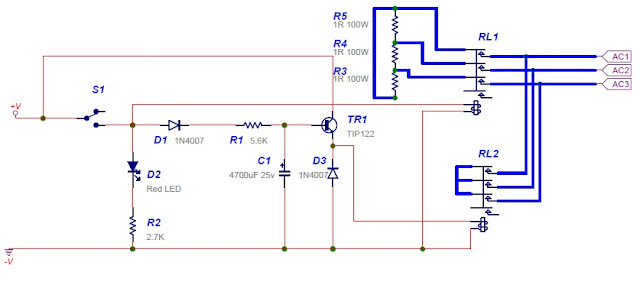

- Installed two CPU fans to help in cooling. This UPS relied exclusively on convection for cooling. Since this UPS was going to be used 24Hrs a day and in inverter-mode, it was getting quite warm especially in Summer due to the higher ambient temperatures. I therefore built a circuit to automatically switch on the fans when the UPS internal temperature reached a certain threshold, set to approximately 40°C. The circuit can be found here.

Specifications - Secondary System (12v):

System DC voltage: 12v

Solar Panels: Two small panels totalling about 40W

Batteries: 1 set of 200 amp hr ex telecoms batteries.

--> Update! Batteries & Panels have been upgraded/replaced!

Usage:

My house loads are the majority 240v 50Hz AC, however I do have some loads which work directly from the DC batteries.

I've listed below the pros and cons of a DC system versus an AC system.

Advantages:

- Running DC loads will eliminate the inverter inefficiencies.

- Transformers and/or chargers inefficiencies are also eliminated (or reduced).

- The inverter can be lower rated since it won't need to handle all the house power.

- DC appliances may be more expensive to purchase.

- DC appliance may be more difficult to source especially from local suppliers.

- A separate DC wiring infrastructure is needed.

- Since DC wiring is low voltage, compensation for voltage looses will have to be made up using extra thick wiring.

Having said all this I still opt for DC loads when possible. Although my DC load is limited, it currently consists of;

- Several 12v DC LED lamps (installed in the kitchen).

- Several 12v DC halogen lamps (installed in the kitchen cupboard).

- 15'' Digital picture frame.

- Cable modem (TV, Telephone and Internet).

- WIFI router

- Reverse Osmosis pump

- Well-pump automatic relay circuit.

- House alarm DC supply.

- Weather station - step-down to 6v.

- Walk-in wardrobe lighting.

- Chimney space heating.

- Electric Shoe Dryer.

- Wardrobes Internal LED lighting. These are enabled automatically on opening the wardrobe doors.

- Panasonic Cordless Base Station

Currently the inverter powers;

- All the house lighting.

- TV, DVD, decoder, Hi-Fi.

- Solar water heater circulating pump.

- Multiple 13amp socket outlets distributed across the house.

Below I have attached pictures of my system.

24v battery sets. Both sets are enclosed in wooden boxes to disable access to my two small children to the battery terminals! Batteries are located in the garage so no problems with regards to heavy gassing.

The 4 Sharp solar panels configured in series/parallel. Each set is installed on it's own pole and feeds its own on/off switch,fuse & amp meter (as shown further down on the DC monitor box). I'm running a common negative 20mm wire for the panels while using a 4mm wire for each set of panels.

General view of my garage wall. Several components are being displayed, listed below;

1) The yellow box is the SMA grid-tie inverter.

2) Below the SMA inverter is the main change-over switch which is used to switch over the house lighting circuit from either the inverter or the local utility provider. The three meters on the same box are a frequency meter, an AC voltmeter and an AC amp meter.

3) The box left of the SMA inverter is a DC junction box with 300 amp switches. 1 red switch is used for the inverter, while the other red switch is a two position switch connected to both 24v battery sets.

4) The 600VA inverter is located on a small shelf (top right hand corner)

7) The small box located at the very bottom is the 12v DC meter box (details further down below).

Below is photo of the several DC meters which I use to monitor the system.

- On the left are four DC amp meters, feed from the solar panels.

- The right-most meter is an amp meter fsd 10amps used to monitor charging from the wind turbine.

- The middle top meter is a 30v fsd meter

- The middle centre meter is a 30 amp meter. It measures the total charging current (Solar + Wind + Charger)

- The middle bottom meter is another 30 amp meter measuring current consumed (Inverter + 12v Chargers + DC appliances)

The box above serves three purposes.

- Monitor 12v system. The left meter is a 5 amp meter measuring the 12v DC load. The right meter is another 5 amp meter measuring the 12v DC charging current. (Solar Panels + Wind Turbine + automatic charger)

- Controls the 12v system.The bottom left switch and fuse control the Power out. The bottom right switch and fuse control the Power in.

- 12v automatic charger. The internal charger monitors the 12v batteries and if the voltage falls below a certain threshold (currently set to 12.4v), the charger automatically kicks in down-converting power from the 24v system. The charger remain on for 5 mins (irrespective if the voltage went up), after which it switches off. If the battery voltage is still low, the charger will switch on again, repeating until the battery voltage is above the threshold. The centre LED indicates when the charger is ON. The charger is based on the popular 7812 (1 amp) fixed voltage regulator, having it's current output increased to 8A thanks to two 2N3055 transistors, mounted on top to help dissipate heat. The heat sinks are clearly visible...

The below two boxes are;

The left box is an LED voltmeter for the 24v system used to indicate the State of charge (SOC).

The right box is a 12v battery charger, taking it's power from the 24v system. The charger is based on the popular 7812 (1 amp) fixed voltage regulator, having it's current output increased to 8A thanks to two 2N3055 transistors mounted inside the box. This charger is mainly used to charge any 12v batteries such as our cars starting batteries.

The below photo is showing a 24v charger. Nothing fancy about it. Just a transformer, two 35amp bridge rectifiers in parallel mounted on a heat sink and a large electrolytic capacitor to smooth out the output. This charger is only used in emergencies, i.e. when the batteries SOC goes down below 50% and no charge from the solar panels is available.