This is the closing article for the fireplace water heating system which I built and now is also being used.

* Part 1 of this article described the chimney heat extraction (heat exchanger) section.

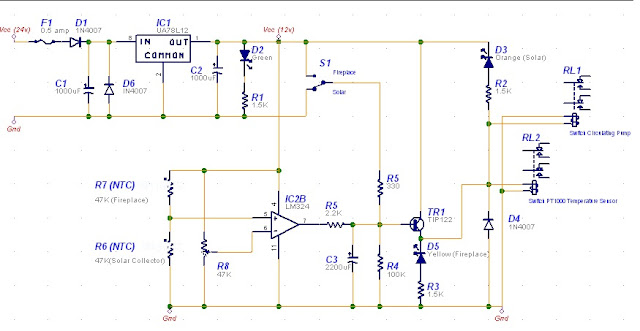

* Article - Differential Controller (Extension), I have described the changes I made to my Steca differential controller to control 2 separate circulating pumps and read 2 different external heat sources.

* In this article - Solar Water System, I have described the hot water system including the common parts with this project.

The chimney heat exchanger has been installed on the first section of the chimney coming out of the roof at a 45 degree angle. The fibreglass enclosing the copper heat exchanger pipe (detailed in Part 1) has been painted in white and the insulated 15mm acorn piping covered in insulation is also visible. Both pipes are shown, feed and return.

The picture below (bottom board) is displaying the new circulating pump (red pump), closed loop pressure gauge, and filling valves connections.

The image below is displaying the completed hot water setup. The upper section is related to the solar collectors, while the bottom section is related to the fireplace chimney collector.

The system works by basically;

1) Cold coolant is circulating through the chimney heat exchanger.

2) The coolant will get heated up as it is circulated around the chimney.

3) It is transfered (pumped) into the hot water tank heat exchanger.

4) The hot coolant will loose it's heat to the surrounding water, thus the water is heated up while the coolant is cooled down.

5) The cooled coolant is circulated back to the chimney heat exchanger (Step 1).

This process is enabled/disabled thanks to the Steca differential controller.

It hasn't been very cold yet here in Malta (at least for me), however on my wife insistence, I am lighting up the fireplace. I do not own any recording equipement / software and therefore I only know what's happening by visiting the Steca monitor while the fireplace is lit and manually recording the temperatures.

The chimney heat exchanger has reached a temperature of 80°C, which is quite good, considering the amout of wood I was burning. I'm pretty sure that I can raise further that temperature however it would get uncomfortably hot inside then.

At this time the year when I hadn't yet build this project, the hot water inside the storge tank will get cold by morning, in the 20s region. As long as I light up the fireplace, the temperature has never gone down below the 30s which is good considering that now during the day, the amount of energy needed (sun or electrical) to increase the hot water temperature to a comfortable level has been drastically reduced.