Central Inverter vs. Micro-Inverter

I'm writing this post because some time ago a relative of mine requested a quote from a local RE supplier and this company recommended that he should install the panels using micro-inverters. The supplier remarked that 'this is the new way of installing panels.' WHAT? True, the technology may be newer than central inverters but that doesn't mean that the central inverters installation is a thing of the past or that micro-inverters are better than central inverters. Both installation types have their pluses and minuses as I'll detail below.

The price for the whole system using micro-inverters went up quite a bit! The strange thing is that the quote was issued after a site visit and it was confirmed that there are NO SHADING issues. So why use micro inverters when shading is not an issue?

Well, quite difficult to answer on behalf of the supplier; however I would like to make these observations.

1) If all panels are facing the same South direction, then one MPPT controller would be enough. Why spend money to purchase an MPPT controller for each panel? Agreed that although the panels would all be rated the same (Power, Voltage, Current), their performance (including their internal resistance) may vary between them, BUT by how much? I don't think that mismatch in panels is an issue in this case simply because most probably the panels would have come from the same manufacturer/batch. Normally the panels may vary +- by a small percentage and that's all, nothing to bother with regards to their overall performance.

2) If not all panels are facing the same direction, but maybe they are split in half, then there are central inverters with 2 or 3 MPPT controllers built in. These will facilitate the installation of the 2 or 3 sets of panels and therefore individual inverters are not needed.

3) If the panels are scattered on the roof all with different directions, then yes I agree that individual MPPT controllers will be needed to optimize the extracted energy from the panels.

4) If there are shading issues, i.e. during a long time of the day, several panels are covered, then again, individual MPPT controllers might be required.

5) Although Micro-inverters are being offered with a longer warranty, I'm still very suspicious about it. Both type of inverters are built from electronic components and both inverters will be placed on the roof next to the panels. The difference is that the Micro-Inverters are placed under the panels while the central inverter can be better positioned in a much cooler location. Electronic components last longer when working in a cool temperature. Therefore a central inverter, due to its better positioning. should last longer since its electronic components are working at a better 'relaxed' temperature.

6) Suppliers and Manufacturers are quoting a better yield from the system, between 5-20%.

Let's take an example here - a 2KW system consisting of 9 panels at 230W each (my actual installation size).

In this case, a 5% increase means we're talking of an extra 103W (equivalent to half a panel.)

In the case of a 20% increase, we're talking of an extra 414W (equivalent to an extra 2 panels). I'm quite susceptible to the 20% increase, however we'll include it also in the comparisons.

In my opinion, if there are no shading issues as mentioned above, and there is more space on the roof, I'd prefer to add an extra panel or two to make up for the decreased efficiency (which is claimed) than adding the micro-inverters. A panel comes with a 25-year warranty and from my experience, they do stick with their warranty claims. I own a couple of 10 year old panels and they still produce power as new.

7) Another issue which is mentioned with regards Central Inverter vs. Micro-Inverter is that micro-inverters are more scalable than Central inverters. If you want to increase the size of the system, it will be just a matter of adding more panels together with their micro inverters. This is a good point, however on installing the system, the central inverter can be purchased to support more panels from day. Thus it will be just a matter of adding the panels once the upgrade is performed. In this case, the upgrade will be cheaper because only the panels will need to be purchased albeit a higher initial cost of the larger central inverter. The upgrade is something which is considered from day 1 due to roof space and panels' location and it's not something which is dreamed of! Therefore the central inverter can be sized accordingly from day 1 to accommodate any upgrade which will happen in the future.

8) Central inverters can be considered as a Single point of failure. Although this is true, in my opinion it still does not justify the use of micro-inverters. A central inverter can be easily replaced since it would have been installed in a better location while micro inverters are all located under the panels. Accessibility of these micro inverters may be a problem to locate.

9) Central inverters come with a standard 5-7 year warranty which can be extended to 10-12 years while micro inverters come with a 20-25 year warranty. Well, I still have to see a micro inverter which has been on the field for 20 years! These warranty claims are based on laboratory tests and predictions while central inverters have been in the field from the time that grid-tie systems have started to mushroom across the world.

To conclude, I always follow the K.I.S.S. (Keep it Simple Stupid) principle. Why add all those electronic devices when they may be not needed (no shading and same orientation)? I think that only time will prove which is the best and therefore, most reliable technology. The central inverters already proved themselves, so we'll just have to wait for the micro-inverters to prove themselves...

Monday, May 4, 2015

The Downfall

On the 7th of November 2014, Malta was hit by a gale force storm. It hit the island in the early afternoon and although lasting for only a few hours, it caused a lot of damage across the island, from trees being uprooted to power towers and walls collapsing.

My wind turbine was not spared!

Below are the photos of the damage suffered. One of the blades got stuck due to the strong wind.

The photo below is displaying one of the guy anchoring support which got detached from the building. It was fixed to the stone building using two 8mm stainless steel raw bolts.

Once one of the guy wires got loose, the stress on the turbine pipe was too much and it collapsed!

After this, I decided that for now I won't be using the wind turbine. I will first build a stronger tower relying less on guy wires since this accident already happened another time!

I'll be posting the details of the new turbine tower once it's ready. I'll definitely build another tower because I have just bought a new set of blades from emarine - Silentwind Silent Air X Air 30 Replacement Power Blades. I obviously haven't tried them yet but these blades seem very promising!

Friday, April 24, 2015

Which Solar (Hot water or PV)?

Hot Water Collector or PV System? Which one has the shortest return on Investment (ROI)?

To arrive at a conclusion, I'll be working out some real-life scenarios (based on my family needs).

I have made the following assumptions in the calculations below:

Water Heater.

--> Based on a family of 5.--> Electric element for both the Solar water heater (SWH) and Electric water heater (EWH) system has been specified as 2KW. This element can be slightly higher for an EWH but average for a SHW system. I've seen SWH installed with a 4KW element. To keep things simple, I'll be working out the consumption using the same 2KW heating element in both cases.

--> My water heating requirements actually reflect ALL my hot water requirements because I'm feeding hot water from the SWH to the washing machine as well, thus eliminating the need to switch on the washing machine heating element. Therefore the SWH will be supplying hot water for all my needs and not only for the bath/kitchen facets. This is not a very common scenario and in fact that's why I use quite a lot of hot water.

--> I'll be using the EWH for 804.5 hours a year while I'll be needing the SWH electric element (when the sun doesn't shine) for 286.5 hours a year.

--> I'm basing the unit of electricity on the 2013 prices, i.e. Eur0.16 per KWH.

--> I have sized the SWH to 200 litres and the EWH to 80 litres.

Usage

SWH electrical heating element average use. Note that for a whole 6 months of the year, I won't be needing to assist my hot water production with electricity.

Jan - 2Hrs x 31days = 62Hrs

Feb - 2Hrs x 28days =56Hrs

Mar - 1Hr x 31days = 31Hrs

Apr - 0Hrs

May - 0Hrs

Jun - 0Hrs

Jul - 0Hrs

Aug - 0Hrs

Sep - 0Hrs

Oct - 0.5Hrs x 31days = 15.5Hrs

Nov - 2Hrs x 30days = 60Hrs

Dec - 2Hrs x 31days = 62Hrs

Total of 286.5Hrs

EWH average use. (Including the Washing machine heating element)

Jan - 3Hrs x 31days = 93Hrs

Feb - 3Hrs x 28days =84Hrs

Mar - 3Hrs x 31days = 93Hrs

Apr - 2Hrs x 30Days = 60Hrs

May - 1.5Hr x 31Days = 46.5Hrs

Jun - 1Hr x 30Days = 30Hrs

Jul - 1Hr x 31Days = 31Hrs

Aug - 1Hr x 31Days = 31Hrs

Sep - 2Hr x 30 Days = 60Hrs

Oct - 3Hrs x 31days = 93Hrs

Nov - 3Hrs x 30days = 90Hrs

Dec - 3Hrs x 31days = 93Hrs

Total of 804.5Hrs

Yearly Calculations

SWH. 2KW (Electrical Element) x 286.5Hrs = 573KWH x Eur0.16 = Eur91.68

EWH 2KW (Electrical Element) x 804.5Hrs = 1609KWH x Eur0.16 = Eur257.44

Yearly difference of Eur165.76

There are several SWH heaters on the market and their prices vary quite a lot depending on certifications, brand etc. I'll be taking an average of Eur1200 for a SWH while Eur120 for an 80 litre EWH. Taking into consideration the grants currently available for SWH, we can reduce the prices to Eur800.

Therefore, Eur800 - Eur120 = Eur680 difference.

Using the yearly operating difference cost of Eur165.76, it will take 4 years to break even the SWH against the EWH.

(I have not taken into account the yearly maintenance fees which are charged by RE suppliers to service the SWH. Unfortunately, the charges are quite high when normally only the cathode rod needs to be replaced!)

PV

--> Sized the system to 2KW. 9 panels x 235 Watts each.--> Feed-in tariff of Eur0.25 per KW (based on 2013 prices).

Yearly Calculations

9 PV @ 235W each = 2115W (Peak Output)

2115W x 0.77 (derating factor) x 5 (average daily hours of sunshine) = 8142.75W or 8KW

Daily average generation = 8KWH x Eur0.25 = Eur2

Yearly, Eur2 x 365days = Eur730

Initial cost. Eur6000 (including government grant (2010))

The payback for the PV system is Eur6000 / Eur730 = 8.2 years.

(I have not taken into account the meter charges).

Warranty.

From the calculations above, 4 years are needed to break-even a SWH while 8.2 years for a PV system. Something to keep in mind however is that normally a SWH is accompanied by a 5-year warranty while a PV system will have 5 years warranty on the inverter and a 20-25 year limited warranty on the PV panel output.

In my opinion, I'm not really worried about the PV panels' warranty, simply because the PV panels are very reliable and I already have experience with some 10 year old panels (and their output is still as new) but I'm more concerned about the inverter. The inverter is a complex electronics device which works every single day (as long as the sun shines) under high loading conditions (90%-100%) of its rated capacity. This places stress on the electronic components and although brand SMA (for example) have a solid product, in my opinion it's the weakest link in a PV system.

Note: Nowadays more electronics are being added to the PV systems to improve their efficiency such as Power Boosters or Power Converters. In my opinion, the more electronics are added, the more prone to failure the system becomes. I'll be more inclined to add an extra panel or two to increase the PV output than add more electronics!

Conclusion.

From the calculations above, a SWH will pay back itself in less time than a PV system. So why is it that people still opt to install a PV system before a SWH or even not install a SWH but go for a PV system only? Maybe a PV system is more attractive? is it because it is also cool to produce your own electricity? Well, in my opinion, the answer is simple ignorance due to the lack of information from the governments & RE companies.

RE suppliers in Malta should know more than everyone else that s SWH ROI is better than a PV system. Nonetheless, they still fail to provide this information. Could it be that the profit margin is better on a PV system?

Another point is that the government grants have failed in this regard. The government should have encouraged families to first install a SWH and then give a better grant to help install a PV system.

Product Review - ICMA Thermostatic Mixer

Product Review - ICMA Thermostatic Mixer

5 years ago I installed an ICMA thermostatic filter bought from a local RE supplier for about 70 Euros. I'm using this mixer to feed the washing machine (WM) since the model of the WM I have, lacked a hot water inlet. In fact most WMs only come with a cold water inlet and the internal heater is then used to warm/heat the washing water. In my case, I already had a 200 litre solar water tank, so it made perfect sense to use some of this hot water to feed directly into the WM.

Just note that I do not feed very hot water to the WM simply because the machine's internal pipes might not handle the hot water. In fact I rarely go above 45°C - 50°C and if the washing load requires the temperature to be higher, I let the internal heater boost the temperature up. Having said this, the thermostatic mixer cannot go higher than 60°C so, to a certain extent, I'm protected against setting too high a temperature.

Benefits of this system are:

1) The WM's internal heater is used much less and therefore less electricity is consumed for a washing load.

2) The washing cycle time is greatly reduced since less (or no time) is spent waiting for the water to heat up.

3) In summer, I use the excess hot water from the hot water storage tank, thus relieving the pressure and stress from the system. Also, during the summer the demand for hot water is significantly less, so the hot water tank is left on a high temperature for an extended period thus causing stress on the various components.

For these last years the mixer has worked well. My only concern was that it would start to get stuck due to the impurities and hard water which we have here in Malta, something which has not happened.

Sunday, August 10, 2014

Failed Wind Turbine Installation

I have a very simple question. Do you place a PV panel in the shade to produce electricity? Do you place a hot water collector in the shade to produce hot water? Obviously NOT, however I witnessed an installation of a wind turbine installed exactly where there is no or very little wind!

I have noticed this installation for over a year now but it seems that the owners are happy with it... The turbine does spin but I guess that's it more of a roof ornament than an operational piece of an engineering.

From the looks of it, the turbine is a 'Proven Wind Turbine'. These turbines are manufactured (or better used to be) in Scotland. They used to be good/solid turbines built like a tank back in the 90s however it seems that the company went bust a couple of years ago.

The pictures below clearly show the wind turbine installation on top of a roof right next to tall buildings. The site is already not ideal because it's at the bottom of a hill however the turbine installation (especially the tower height) continues to make things worse.

A small wind turbine (500W - 1KW) should be installed at least 30 feet above all buildings with a clear radius of at least 500 feet. In Malta these guidelines are not always possible to adhere to due to our zoning restrictions and overly populated/built country however at least, the height should be maintained. The taller the tower the better, because the best and consistent wind is found at high altitudes where there is very little turbulence.

The picture below clearly shows buildings at the same height of the turbine on the right!

Why did I bother to write about this turbine? Simply because this turbine is installed at MCAST in Paola where most probably, studies are being conducted to determine wind power feasibility!!!!

I have noticed this installation for over a year now but it seems that the owners are happy with it... The turbine does spin but I guess that's it more of a roof ornament than an operational piece of an engineering.

From the looks of it, the turbine is a 'Proven Wind Turbine'. These turbines are manufactured (or better used to be) in Scotland. They used to be good/solid turbines built like a tank back in the 90s however it seems that the company went bust a couple of years ago.

The pictures below clearly show the wind turbine installation on top of a roof right next to tall buildings. The site is already not ideal because it's at the bottom of a hill however the turbine installation (especially the tower height) continues to make things worse.

A small wind turbine (500W - 1KW) should be installed at least 30 feet above all buildings with a clear radius of at least 500 feet. In Malta these guidelines are not always possible to adhere to due to our zoning restrictions and overly populated/built country however at least, the height should be maintained. The taller the tower the better, because the best and consistent wind is found at high altitudes where there is very little turbulence.

The picture below clearly shows buildings at the same height of the turbine on the right!

Why did I bother to write about this turbine? Simply because this turbine is installed at MCAST in Paola where most probably, studies are being conducted to determine wind power feasibility!!!!

Wednesday, August 6, 2014

The Electric Experience

This post is dedicated to my experience driving an electric car for eight weeks.

Back in 2012, I applied to be selected as a volunteer to experience driving an electric car. Funded by the EU, I applied for the Demo EV project (Demonstration of the Feasibility of Electric Vehicles towards Climate Change Mitigation) Project no. LIFE10/ENV/MT/088)

25th July 2014

Go Clean, Go Silent, Go Electric

Finally I was handed over my chosen car. I opted for the MIEV. Some basic features of this car;

Week 1 (25th July --> 31st July)

Distance Travelled: 177Km

Number of Charges: 2 (Home & Charging Post (CP))

Air Conditioner: Not used.

I performed my first charge at home to measure exactly the power requirements. Using a power meter, I have the following data :-

Voltage: 248.33v

Current Sourced: 12.58amps

Power Factor: 9

Power: 3124 Watts.

Peak Power: 3142.Watts

Charge Capacity Before: 31%

Charge Capacity After: 100%

Total Power used: 11.3KW

Unit Cost per KW: Euro 0.16c

* I'm basing the KW cost on last year's rates simply because I haven't yet received a bill for this year. I'll revise once I actually receive a bill from ARMS!

** I'm ignoring the fact that I have PV panels at home in which case the cost would have been much cheaper.

Total Cost for reaching full charge: Euro 1.81c

Summary:

To charge to 100% from 31%, 11.3KW or Euro 1.81c were needed.

Therefore a full charge from 0% to 100%, 16.37KW or Euro2.62 will be needed.

And the most important question of all! How much does it cost to travel with the car? Well basing on my first 2 charges;

Distance Travelled: 157Km

Cost for travelling 157Km: Euro3.1312

That's 50.14Km per Euro.

Week 2 (1st Aug--> 8th Aug)

For my 2nd week, I have partially (66Km) switched on the AC as shown below.

Total cost for travelling 352Km is Euro7.25

That's 48.55Km per Euro, obviously slightly less than week 1 due to the AC use.

As the weeks go by, I'll be able to draw a much more accurate average and will also compare to my other two internal combustion (ic) cars.

I have charged a total of 4 times for these couple of weeks, i.e. an average of twice a week. I'm very conscious when it comes to battery state, (i.e. what's left in the tank) and therefore I almost always charge when I'm slightly below half full.

A common question I get asked is, how long does it take to charge?

Well it depends on several factors:

1) How much charge is needed, i.e. how much is left in the 'tank'

2) Fast or Normal Charge.

Option 2 is currently out of the question because I was not given the 'fast charge' cable and it actually needs a 3 phase supply. From the manual, it is claimed that in 30mins, the battery can reach an 80% charge.

Option 1 can be easily calculated.

The battery capacity is 16KW. Assuming that we're charging from a flat state (which will never be),

and the charger consumes 3.12KW (let's round down to 3KW), then 16/3 = 5.33 hours. I would therefore assume that 5.5 hours will be needed to reach a full charge.

Most people will find this timing a show stopper! 'Why wait 5 hours to charge when I can fill up in a couple of minutes at the gas station?' Well, an electric car needs also a change of mentality and planning. With an electric car you do not leave the battery to drain and then expect to charge up in a couple of minutes.

There are a number of good times when to charge. The most obvious is at night. While the body is charging up for the next day during sleep, the car can also be charged up for the next day to provide a day or two of driving. I also find it convenient to charge while at work. I spend 8+ hours at work not using the car, enough time to leave the car plugged into a Charging Pillar (CP).

Week 3 (9th Aug --> 15th Aug)

I'll be continuing to drive with both the AC ON and OFF to better reflect my normal driving conditions.

Week 5 (22nd August --> 29nd August)

5 weeks passed.

From the questions I'm normally asked, I've noticed that people are mostly concerned mostly about 2 things;

1) Charging times.

2) Battery warranty.

Charging Times. On average I spend from 1 to 2 hours (Winter traffic jams) behind the wheel each day. This leaves the remaining 22 hours when the car is idle parked somewhere doing nothing. This time can be easily utilised to recharge the car. I had calculated that in about 5.5 hours, you can recharge the car from 0% to 100%. Therefore there is ample time in a day to fully recharge the car (from flat) each day! Much more than anyone will need simply because to drain the car battery to 0%, you'll need to travel about 160Km. I therefore cannot understand why this question keeps coming up? It doesn't matter how long the car needs to recharge simple because there is ample time in a 24 hour day to recharge the car.

In my opinion, It's more of a matter of change of routine than anything else.

Battery Warranty. People are very concerned about the 5 years battery warranty. Well let's forget the EV and instead image that we're purchasing an LED TV, a home appliance or else for who installed a grid-tie PV system - the Inverter which carries a 5 year warranty. Are we concerned with the 5 years warranty? Not really I assume, so why is it that the warranty on the car battery is an issue. The warranty is just a guarantee. The warranty is NOT the lifetime expectation of what we're buying. It does not mean that after the warranty of whatever we're purchasing expires, the item becomes scrap, so what's different from an EV battery. I can't image buying a washing machine with 5 years warranty and I have to replace it after the warranty period!

On the other hand, I have to admit that batteries do not have a very good reputation among anyone. Everyone associates batteries with car batteries which have a very short life. The EV battery is NOT a normal 12v cheap starting battery. The EV battery is a long-life complex Lithium Ion battery. Why complex? Complex because it's managed by a complicated battery charging/monitoring system and not a simple car alternator.

(Apart from the 12v starting batteries, there are also batteries with a better reputation and longer life such as deep cycle batteries and forklift batteries. If properly maintained, these batteries can last between 5 to 15 years, so what's different from an EV Lithium Ion battery?)

A good primer on EV batteries can be found here at Home Power. This website is dedicated to RE stuff.

Statistics.

KM travelled split by AC usage.

Totals for the past 5 weeks. For just 20Eur, I travelled 1009 KM.

With my 'normal' car, I'll spend 20Eur on diesel in just one week. This is were the financials will start making sense. At the end of my trial period, I'll be doing a full comparison with both a Petrol and Diesel car.

Recharge times. This number can be a bit misleading simply because I have recharge more than 2 times a week for a shorter duration, basically charging more when not using the car.

Back in 2012, I applied to be selected as a volunteer to experience driving an electric car. Funded by the EU, I applied for the Demo EV project (Demonstration of the Feasibility of Electric Vehicles towards Climate Change Mitigation) Project no. LIFE10/ENV/MT/088)

25th July 2014

Go Clean, Go Silent, Go Electric

Finally I was handed over my chosen car. I opted for the MIEV. Some basic features of this car;

- Fully Electric.

- Expected range on a full charge - 160Km

- 47KW Power Output.

- 180 Nm Torque.

- Battery Type - Lithium Ion

- Battery Voltage - 330v

- 16KW Battery Pack.

Week 1 (25th July --> 31st July)

Distance Travelled: 177Km

Number of Charges: 2 (Home & Charging Post (CP))

Air Conditioner: Not used.

I performed my first charge at home to measure exactly the power requirements. Using a power meter, I have the following data :-

Voltage: 248.33v

Current Sourced: 12.58amps

Power Factor: 9

Power: 3124 Watts.

Peak Power: 3142.Watts

Charge Capacity Before: 31%

Charge Capacity After: 100%

Total Power used: 11.3KW

Unit Cost per KW: Euro 0.16c

* I'm basing the KW cost on last year's rates simply because I haven't yet received a bill for this year. I'll revise once I actually receive a bill from ARMS!

** I'm ignoring the fact that I have PV panels at home in which case the cost would have been much cheaper.

Total Cost for reaching full charge: Euro 1.81c

Summary:

To charge to 100% from 31%, 11.3KW or Euro 1.81c were needed.

Therefore a full charge from 0% to 100%, 16.37KW or Euro2.62 will be needed.

And the most important question of all! How much does it cost to travel with the car? Well basing on my first 2 charges;

Distance Travelled: 157Km

Cost for travelling 157Km: Euro3.1312

That's 50.14Km per Euro.

Week 2 (1st Aug--> 8th Aug)

For my 2nd week, I have partially (66Km) switched on the AC as shown below.

Total cost for travelling 352Km is Euro7.25

That's 48.55Km per Euro, obviously slightly less than week 1 due to the AC use.

As the weeks go by, I'll be able to draw a much more accurate average and will also compare to my other two internal combustion (ic) cars.

I have charged a total of 4 times for these couple of weeks, i.e. an average of twice a week. I'm very conscious when it comes to battery state, (i.e. what's left in the tank) and therefore I almost always charge when I'm slightly below half full.

A common question I get asked is, how long does it take to charge?

Well it depends on several factors:

1) How much charge is needed, i.e. how much is left in the 'tank'

2) Fast or Normal Charge.

Option 2 is currently out of the question because I was not given the 'fast charge' cable and it actually needs a 3 phase supply. From the manual, it is claimed that in 30mins, the battery can reach an 80% charge.

Option 1 can be easily calculated.

The battery capacity is 16KW. Assuming that we're charging from a flat state (which will never be),

and the charger consumes 3.12KW (let's round down to 3KW), then 16/3 = 5.33 hours. I would therefore assume that 5.5 hours will be needed to reach a full charge.

Most people will find this timing a show stopper! 'Why wait 5 hours to charge when I can fill up in a couple of minutes at the gas station?' Well, an electric car needs also a change of mentality and planning. With an electric car you do not leave the battery to drain and then expect to charge up in a couple of minutes.

There are a number of good times when to charge. The most obvious is at night. While the body is charging up for the next day during sleep, the car can also be charged up for the next day to provide a day or two of driving. I also find it convenient to charge while at work. I spend 8+ hours at work not using the car, enough time to leave the car plugged into a Charging Pillar (CP).

Three very exited boys on board the 'electric'

Week 3 (9th Aug --> 15th Aug)

I'll be continuing to drive with both the AC ON and OFF to better reflect my normal driving conditions.

Week 5 (22nd August --> 29nd August)

5 weeks passed.

From the questions I'm normally asked, I've noticed that people are mostly concerned mostly about 2 things;

1) Charging times.

2) Battery warranty.

Charging Times. On average I spend from 1 to 2 hours (Winter traffic jams) behind the wheel each day. This leaves the remaining 22 hours when the car is idle parked somewhere doing nothing. This time can be easily utilised to recharge the car. I had calculated that in about 5.5 hours, you can recharge the car from 0% to 100%. Therefore there is ample time in a day to fully recharge the car (from flat) each day! Much more than anyone will need simply because to drain the car battery to 0%, you'll need to travel about 160Km. I therefore cannot understand why this question keeps coming up? It doesn't matter how long the car needs to recharge simple because there is ample time in a 24 hour day to recharge the car.

In my opinion, It's more of a matter of change of routine than anything else.

Battery Warranty. People are very concerned about the 5 years battery warranty. Well let's forget the EV and instead image that we're purchasing an LED TV, a home appliance or else for who installed a grid-tie PV system - the Inverter which carries a 5 year warranty. Are we concerned with the 5 years warranty? Not really I assume, so why is it that the warranty on the car battery is an issue. The warranty is just a guarantee. The warranty is NOT the lifetime expectation of what we're buying. It does not mean that after the warranty of whatever we're purchasing expires, the item becomes scrap, so what's different from an EV battery. I can't image buying a washing machine with 5 years warranty and I have to replace it after the warranty period!

On the other hand, I have to admit that batteries do not have a very good reputation among anyone. Everyone associates batteries with car batteries which have a very short life. The EV battery is NOT a normal 12v cheap starting battery. The EV battery is a long-life complex Lithium Ion battery. Why complex? Complex because it's managed by a complicated battery charging/monitoring system and not a simple car alternator.

(Apart from the 12v starting batteries, there are also batteries with a better reputation and longer life such as deep cycle batteries and forklift batteries. If properly maintained, these batteries can last between 5 to 15 years, so what's different from an EV Lithium Ion battery?)

A good primer on EV batteries can be found here at Home Power. This website is dedicated to RE stuff.

Statistics.

KM travelled split by AC usage.

Totals for the past 5 weeks. For just 20Eur, I travelled 1009 KM.

With my 'normal' car, I'll spend 20Eur on diesel in just one week. This is were the financials will start making sense. At the end of my trial period, I'll be doing a full comparison with both a Petrol and Diesel car.

Recharge times. This number can be a bit misleading simply because I have recharge more than 2 times a week for a shorter duration, basically charging more when not using the car.

Week 8 (Last week)

8 weeks passed and it was time to hand back over my EV.

Statistics.

Km travelled split by week & AC usage.

Km travelled split by week only.

Total distance travelled and total cost to recharge.

As seen above, I did 1732Km in 8 weeks and needed Eur36 to charge. (always based on 1 unit = Eur0.16). This translates to 48Km per unit of electricity or 48Km per Eur0.16Eur.

Comparing to my other 2 cars;

A 14 year old diesel, I worked out that I can make 1Km for Eur0.12, while a 1 year old Petrol, I worked out that I can make 1Km for Eur0.10. On the other hand, the EV needs Eur0.02 per Km.

Therefore the EV works out to be 80% cheaper (fuel cost) when compared to the Petrol car.

Conclusion

I was very satisfied with my EV. I enjoyed every minute of it. I obviously loved it's low consumption, no noise and high torque. Will I go for an EV for my next car? Definitely YES!

Tuesday, August 5, 2014

New Batteries (Off Grid System)

Finally, the new forklift batteries for my off-grid system arrived. After 7 years of service from my old forklift battery set, it was time to replace them since the old batteries were showing signs of fatigue & started failing. I had already replaced 3 of my old cells and the overall reduced capacity was a clear sign that the batteries had reached their end of their service life.

A short history about my old battery set. They were not new at all but had been scrapped from a factory since they were removed from a fork lifter. A good friend (and neighbour) Mario who used to work there, suggested to me to take them in and give them a try. I selected the best 12 cells (out of 24) and kept the remaining good batteries as spare. Well, it was really a good decision to keep them since the 12+ cells which I salvaged gave me 7 years of service.

The new batteries I purchased are of the same time. These are:-

Brand: Fulmen Forklift Batteries

Voltage: 2.11v per cell

Amp Hour: 680AH

Storage Capacity: 2.11v x 680AH x 12(Cells) = 17217.6WH or 17.21KWH

At a max of 50% DOD, 8608WH or 8.60KWH of usable capacity.

Size

Width: 20cm

Depth: 12cm

Height: 46cm

Weight: Very heavy ~ 30Kg each!

Below is a photo of the installed batteries inside my existing battery box. Note the additional wiring which I have prepared to tap and measure each individual cell voltage.

Every month, I perform a check on the batteries and besides reading the SG of all cells, I need to also check the individual cell voltages. From these two measurements I'll be able to decided when an Equalisation charge is needed.

And next to the battery box, The photo below is showing the fuse box and the battery desulpahtors. One of the desulpahtors is 24v connected to the new battery set while the other desulpahtor is connected to my 12v battery system.

The new battery monitoring system. I installed a digital voltage meter across all the 12 cells. These voltmeters can measure a DC voltage from 0v to 10v with an accuracy of +-0.1%. The supply voltage is quite flexible 4v - 30v.

Below is the circuit diagram of the battery monitoring system. I used two separate power supplies to power the 12 digital meters.

The digital voltmeter connections are pretty straightforward. Each voltmeter will measure a cell voltage and therefore the negative (-) and sense wires need to go across the individual cells.

Monday, March 10, 2014

Fireplace water heating system (Part 2)

This is the closing article for the fireplace water heating system which I built and now is also being used.

* Part 1 of this article described the chimney heat extraction (heat exchanger) section.

* Article - Differential Controller (Extension), I have described the changes I made to my Steca differential controller to control 2 separate circulating pumps and read 2 different external heat sources.

* In this article - Solar Water System, I have described the hot water system including the common parts with this project.

The chimney heat exchanger has been installed on the first section of the chimney coming out of the roof at a 45 degree angle. The fibreglass enclosing the copper heat exchanger pipe (detailed in Part 1) has been painted in white and the insulated 15mm acorn piping covered in insulation is also visible. Both pipes are shown, feed and return.

The picture below (bottom board) is displaying the new circulating pump (red pump), closed loop pressure gauge, and filling valves connections.

The image below is displaying the completed hot water setup. The upper section is related to the solar collectors, while the bottom section is related to the fireplace chimney collector.

The system works by basically;

1) Cold coolant is circulating through the chimney heat exchanger.

2) The coolant will get heated up as it is circulated around the chimney.

3) It is transfered (pumped) into the hot water tank heat exchanger.

4) The hot coolant will loose it's heat to the surrounding water, thus the water is heated up while the coolant is cooled down.

5) The cooled coolant is circulated back to the chimney heat exchanger (Step 1).

This process is enabled/disabled thanks to the Steca differential controller.

It hasn't been very cold yet here in Malta (at least for me), however on my wife insistence, I am lighting up the fireplace. I do not own any recording equipement / software and therefore I only know what's happening by visiting the Steca monitor while the fireplace is lit and manually recording the temperatures.

The chimney heat exchanger has reached a temperature of 80°C, which is quite good, considering the amout of wood I was burning. I'm pretty sure that I can raise further that temperature however it would get uncomfortably hot inside then.

At this time the year when I hadn't yet build this project, the hot water inside the storge tank will get cold by morning, in the 20s region. As long as I light up the fireplace, the temperature has never gone down below the 30s which is good considering that now during the day, the amount of energy needed (sun or electrical) to increase the hot water temperature to a comfortable level has been drastically reduced.

Monday, February 3, 2014

Chimney space heating

Project Description

My fireplace (located on the ground floor) has been installed in a way that the chimney passes through the main bedroom (located on the first floor) before emerging from the roof. The idea being that heat generated from the chimney pipe will be radiated also in the bedroom before being lost once it reaches outside. I liked the idea however the implementation is very poor and inefficient. In fact, very little heat is actually transferred to the bedroom. The main reason is that the original system relied only on the fact that natural air will flow around the chimney pipe and get heated in the process (through both convection and radiation). My problem is that very little air can flow around the chimney pipe since it has been enclosed in gypsum board. There are only two holes through which air can flow, a 15x15cm hole at the bottom and a 20x20 hole at the top. Cold air will theoretically be sucked from the bottom and get heated as it flows out from the upper hole. In theory that's what is should happen however in practice, very little heat is transferred!

To improve this concept, I have installed a fan at the bottom opening which sucks in cold air and pushes it against the chimney pipe, while four smaller fans installed at the top opening will push the warm air out from the chimney enclosure into the bedroom.

Circuit Description

The designed circuit is based on the popular quad opamp LM324. It will control a small number of fans, these switching on depending on temperature, i.e. once the chimney temperature rises beyond a pre-defined threshold, the fans will be powered on (slow speed). Once a second pre-defined threshold is reached, the fans are powered fully on. This two-step switching has been implemented because these fans are installed in a bedroom and it's very undesirable to have a number of fans fully blowing at night. Also, the chimney will eventually get cooler at night because the fire will diminish and therefore it's useless having the fans blowing at full speed.The circuit is powered by a 12v supply. Supply regulation is not critical. In my case, I've used the house 12v which I have wired around the house. I'm getting this supply from a 12v battery, charged by a solar panel. More details about the off-grid system can be found here. Capacitors C2 and C3 have been included to stabilise the supply rail.

I've used one of the opamps (IC1D) to generate a very stable 10v supply. This 10v is used as a reference voltage for the other two comparators.

The temperature is measured using a 47K (ntc) thermistor. An ntc thermistor will decrease it's resistance as the temperature rises.

The two comparators are IC1B and IC1C, both are identically wired with preset P1 setting the temperature (reference voltage) for IC1B and preset P2 setting the temperature (reference voltage) for IC1C. This reference voltage is applied to the opamps Inverting input.

The non-inverting input is fed through resistors R9 and thermistor R10. As the temperature rises, the voltage at this junction will increase and therefore the voltage at the opamp's non-inverting input will increase.

Opamps IC1B and IC1C outputs are buffered using transistors TR1 and TR2 respectively. These provide enough current gain to power the fans. Resistor R8 has been specifically choosen to power the fans at a lower speed. Please note that both transistors have to be placed on a small heatsink. Although the transistors will operate only as switches, i.e. either fully off or fully on, they will get pretty hot with as little as 0.5amps of current.

The below image is displaying the finished circuit board built on a small vero board. The circuit will be installed in a 6x3 conduit box.

The image below is showing the connections and major components of the circuit.

The image below is showing the location/conduit box into which the circuit has been placed. I have added an external switch to turn off the circuit during the warm months.

The next two images are showing the bottom and top holes into which the fans have been installed. The chimney pipe is installed in the corner of the room enclosed with gypsum boards. The bottom fan will suck cold air and push it into the chimney enclosure. The sucked in air will heat up as it passes next to the hot chimney pipe and will eventually be blown out from the top fans into the room, thus heating up the room.

Thursday, January 30, 2014

Electric Shoe Dryer

This is not actually a Renewable Energy project but more of a weekend project necessitated following a rainy week. In Winter it's always a nightmare to dry up wet shoes and putting them in front of a very hot source (such as a heater or fire) will risk of ruining the shoes. A more gentle approach is necessary, number one option being to place them outside in the sun, however when this is not possible, this solution will dry up the shoes gently without damaging them.

Two very important points which must be taken into account for a successful built are;

1) The sheet thickness. A thicker sheet will provide better heat conduction inside the metal.

2) The resistors placing.

Both will help to reduce 'hot spots' and provide a better heat distribution across the whole surface. 'Hot spots' occur when an area gets hotter than the rest. This normally occurs just over the heat source (power resistors) and is not desirable (at least in this application).

I then fixed 3 wooden legs to the aluminium sheet to elevate the power resistors from the floor. Finally I covered the aluminium sheet with a thick cloth to help reduce further 'hot spots'.

*Heat transfer paste will help in transferring the heat from the resistors to the sheet and is recommended that it is used.

An underneath view of the finished assembled shoe dryer.

Here I started fixing the thick cloth to the upper side. I have used Pattex glue and held everything in place using G clamps.

An underneath view of the finished show dryer including the thick cloth.

An underneath view of the finished show dryer including the thick cloth.

The finished shoe dryer.

The finished shoe dryer.

The resistors are connected to an external 24v power source. I connected it to my off-grid 24v setup. I have not shown in the diagram however a fuse is indispensable for these types of circuit. A 5 amp in-line fuse should do the job nicely.

Diode D1 in series with resistor R5 provide an indication when the Dryer is on.

Using ohms law V=IR

The voltage is 25.4v (12.7v x 2)

The total resistance is 8.8 (2.2 x 4) ohms

Therefore the current is 25.4v / 8.8 = 2.88 amps

Using the Power formula P=IV

The voltage is 25.4v (12.7v x 2)

The current is 2.88 amps

Therefore the power dissipated is about 73W

In actual fact, the power dissipated would be slightly less simple because the battery voltage would be lower due to other loads. Also, power is wasted in the wiring. In my case, I'm not plugging in the resistors right next to the batteries but I'm using the 24v off-grid wiring which I have going round the house. The length of wire is introducing extra resistance.

Dryer Description

The built is pretty simple and straightforward. I used a sheet of aluminium (30cm length x 45cm width) and bolted underneath 4 power resistors. The heat generated by the power resistors will be transferred to the sheet which will be eventually radiated to the shoes to dry them up.Two very important points which must be taken into account for a successful built are;

1) The sheet thickness. A thicker sheet will provide better heat conduction inside the metal.

2) The resistors placing.

Both will help to reduce 'hot spots' and provide a better heat distribution across the whole surface. 'Hot spots' occur when an area gets hotter than the rest. This normally occurs just over the heat source (power resistors) and is not desirable (at least in this application).

I then fixed 3 wooden legs to the aluminium sheet to elevate the power resistors from the floor. Finally I covered the aluminium sheet with a thick cloth to help reduce further 'hot spots'.

*Heat transfer paste will help in transferring the heat from the resistors to the sheet and is recommended that it is used.

An underneath view of the finished assembled shoe dryer.

Here I started fixing the thick cloth to the upper side. I have used Pattex glue and held everything in place using G clamps.

An underneath view of the finished show dryer including the thick cloth.

An underneath view of the finished show dryer including the thick cloth. The finished shoe dryer.

The finished shoe dryer.Circuit Description

The circuit is very simple. It just consists of 4 power resistors (R1, R2, R3, R4) rated 2.2 ohms 100W wired in series. The values are not critical and in fact I used whatever I had in stock. I would have preferred if the resistance was slightly higher to keep the current/power further down. The power rating of the resistors could also have been less since I'll be just using a small fraction of their power dissipation. The advantage of the higher power rating is that the components will not operate next to their maximum rating and should last longer.The resistors are connected to an external 24v power source. I connected it to my off-grid 24v setup. I have not shown in the diagram however a fuse is indispensable for these types of circuit. A 5 amp in-line fuse should do the job nicely.

Diode D1 in series with resistor R5 provide an indication when the Dryer is on.

Using ohms law V=IR

The voltage is 25.4v (12.7v x 2)

The total resistance is 8.8 (2.2 x 4) ohms

Therefore the current is 25.4v / 8.8 = 2.88 amps

Using the Power formula P=IV

The voltage is 25.4v (12.7v x 2)

The current is 2.88 amps

Therefore the power dissipated is about 73W

In actual fact, the power dissipated would be slightly less simple because the battery voltage would be lower due to other loads. Also, power is wasted in the wiring. In my case, I'm not plugging in the resistors right next to the batteries but I'm using the 24v off-grid wiring which I have going round the house. The length of wire is introducing extra resistance.

Thursday, January 16, 2014

Reducing water wastage while waiting for your hot water

This small plumbing modification was needed to stop/reduce wasting cold water down the drain while waiting for the hot water from the hot water tank to reach the hot water outlets which are located in the bathrooms and kitchen.

In my case, I have a 200 litres hot water tank installed in the washroom on the 2nd floor. The furthest hot water outlet is located approximately 25 meters away of pipes. The piping is 22mm insulated acorn pipe (20mm internal diameter). Calculating the volume of water stored in the pipe which will need to be displaced for the hot water to reach the outlet using the supplied measurements, it equates to about 0.78 litres of water. Using the below formula,

V = 3.142 x 0.01m (pipe radius) x 25 (pipe length) = 0.78 litres

In practice the wasted water will be much higher. I measured the water in a measuring tank and I actually displaced 4/5 litres until the water coming out from the tap was comfortable hot enough. The difference between the calculated & actually displaced water is mainly due to heat losses in the 25m pipe run (even though the pipe is well insulated).

Now this is only if you need hot water once a day which is not the case (at least at my house) were we're a family of five. It's obvious that a large amout of water which will be wasted on a daily basis just in 'waiting' for the hot water.

The solution was easy, I installed a valve just outside my ground floor bathroom (furthest point) which is used/opened to direct the hot water back up to the roof tank using an already existing plumbing. In my case I used the water pipe which is used to pump the well water to the roof tank. Since the hot water plumping circuit is on a pressure pump, there was absolutely no problem for this solution to work since the pressure pump will come on and push the water back to the tank.

The picture below is showing the 'return' red valve which is used to return cold water back to the roof tank until the hot water reaches the valve (downstairs). It is easily accessible by just opening a window and opening the valve for a some time.

Monday, October 7, 2013

Lightning-protection system

Earthing

In Malta (and I assume in most, if not all countries), earthing is mandatory. This is provided by the mandatory earth electrode which must be located next to the power meter. For redundancy sake, I have added a further two earth electrodes, all installed (dug) in different locations. In fact the additional electrodes have been installed in the yard. All the electrodes are interconnected using 6mm copper cable to maintain the same earth potential.

A 10mm cable runs from the electrodes to the roof were I have all the photovoltaic panels, panel structures and wind turbine earthed.

To protect all my house electrical and electronic equipment, I have constructed a number of lighting protection circuits. These are;

1) Circuit to protect my mains supply - 240v AC 50Hz, being supplied either from my local power provider (Enemalta) or from the inverter.

2) Circuit to protect my 24v DC house wiring system.

3) Circuit to protect power from the 'off-grid' panels feeding the batteries and off-grid inverter.

4) Circuit to protect power from the 'grid-tie' panels.

1) Circuit to protect my mains supply, being supplied either from my local power provider (Enemalta) or from the inverter.

The basic and most important component is the Varistor, and in fact I have used quite a number of them.

Surge protection is provided between;

a. Live <--> Neutral. This is the most important and in fact most electronic equipment will be already protected internally using a similar setup.

b. Live <--> Earth. This is also very important to protect since the potential difference between Neutral and Live should be close to the potential difference between Live and Earth.

c. Neutral <--> Earth. The voltage difference between Earth and Neutral should be close to 0 because the Neutral is actually earthed at the distribution centre. However a small potential difference does exist (<10v) and this protection is intended to safeguard in case the Neutral potential is raised with respect to the Earth.

Components List

SA1, SA2: Miniature Gas Filled, 20kA/20A

C1, C2, C3: 150nF 300v AC Capacitors

RV1-RV5: 300v Varistors

RV6-RV10: 300v Varistors

RV11-RV15: 30v Varistors

D1: Green LED

R1: 150K 0.25w

2) Circuit to protect my 24v DC house wiring system.

The below circuit is used to protect against any surges which might get through to the DC system (batteries, off-grid inverter, house lights etc). Protection is mainly provided by the varistors, however diodes D1 and D2 are connected in reverse polarity across the supply to protect against any back emf.

Components List

C1: 100nF

C2: 4700uF 50v

RV1-RV5: 30v Varistors

D1: Green LED

R1: 1.5K 0.25w

D2, D3: 10Amp Diodes

3) Circuit to protect power from the 'off-grid' panels.

This circuit sits exactly under the off-grid panels and serves as the primary protection to my DC system against any voltage surges/spikes.

Components List

C1, C2, C3, C4: 4700uF 50v

RV1-RV2: 50v Varistors

D1, D2: 10Amp Diodes

F1, F2: 5 amp fuses

4) Circuit to protect power from the 'grid-tie' panels.

This circuit sits exactly between the grid-tie panels and the grid-tie inverter. It was not really necessary because this type of circuit already exist internally in the inverter however I wanted to provide extra external protection. I prefer this circuit blowing up then my expensive SMA inverter!

Components List

C1: 470uF 400v

C2: 100nF 1000v

RV1-RV3: 360v Varistors

D1: 10Amp Diode

Friday, July 26, 2013

Differential Controller (extension)

Scope

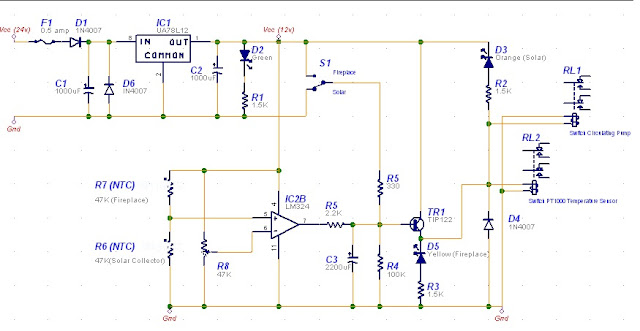

The scope of this circuit is to use my existing Steca TR0301 differential controller, but connected to two heat sources (log fireplace and solar collector) and two circulating pumps. The simple circuit below will enable me to continue using the TR0301 controller while at the same time reading temperature from two heat sources and controlling two independent circulating heat pumps. The storage tank is the common factor.

Background

In Malta, the log fireplace is only switched on for a maximum of three months (at least in my case) and therefore I couldn’t justify purchasing another differential controller just to be used for only three months. Also, I do not light the fireplace during the day when the solar collector is working. In fact the solution I’ll be explaining can only have one heat source active at a time.The circuit has been built to be reliable using the least number of electronic components. Since the majority of the time the controller will be controlling heat from the solar controller, the circuit has been designed to be ‘off’ the majority of the time, i.e. the relays de-energised.

Circuit Description

The circuit is powered from the house 24v DC supply. This is stepped down using IC1 7812 linear voltage regulator. IC1 is fed via fuse F1 and diodes D1and D6 protect the circuit in case of a polarity reversal. Capacitors C1 and C2 provide supply smoothing while the green LED D2 indicates that the 12v supply is available.

The circuit is based on the quad opamp LM324. In this application I’ll be using only one of the four opamps. Pin 6 (Inverting input) is pre-set to approximately half the supply voltage *, while Pin 5 (non-inverting input) is set by thermistors R6 and R7. These thermistors are identical 47K NTC type located at the solar collector and the other attached to the chimney pipe. NTC thermistors reduce resistance once the temperature is raised.

Two scenarios are available;

1)

R6 > R7 i.e. Solar Collector warmer than Fireplace.

When the solar collector is warmer than the fireplace, the resistance of R6 will be less than R7 and therefore Pin 5 is taken to Ground. Assuming Pin 6 set to 6v (half the supply voltage), and therefore Pin 6 voltage is higher than Pin 5, the opamp output will be low. Transistor TR1 is OFF and both relays OFF. While OFF,

·

RL1 will be connecting the differential

controller to the solar circulating pump

·

RL2 will be connecting the differential controller to the Steca PT1000 temperature

sensor located at the solar collector

2)

R7 > R6 i.e. Fireplace warmer than Solar Collector.

When the fireplace is warmer than the solar collector, the resistance of R7 will be less than R6 and therefore Pin 5 is taken high to the supply voltage. Assuming Pin 6 is set to 6v (half the supply voltage), Pin 5 voltage is higher than Pin 6; the opamp output will be high. Transistor TR1 is ON and both relays are ON.

·

RL1 will be connecting the differential

controller to the fireplace circulating pump

·

RL2 will be connecting the differential

controller to the Steca PT1000 temperature sensor located at the fireplace

chimney.

Subscribe to:

Posts (Atom)